May

Types of Milling Machine & Features

- days

- Hours

- Minutes

- Seconds

With a fast-moving multi-tooth cutter, the milling machine eliminates metal. A milling cutter is a multi-tooth cutter with several teeth. Longitudinal, vertical, and transversal feeds are all possible.

Milling machines come in a variety of sizes, shapes, and configurations.

Types of knees and columns

milling machine by hand

Machine that mills plainly

Milling machine with universal use

Milling machine that works vertically

Milling machine with planer

Beds that are permanently installed

Duplexes, triplexes, and simplexes are all types of transmission systems. CNC milling of a special type

The most frequent type of milling machine for shop work is the column and knee type milling machine, which is used to work on tiny workpieces. A bed-type machine is utilized for larger items. There are four different types of it. Here are detailed introduction to column and knee type milling machine: https://bitzean.com/read-blog/1764_types-and-parts-of-column-and-knee-type-milling-machine.html

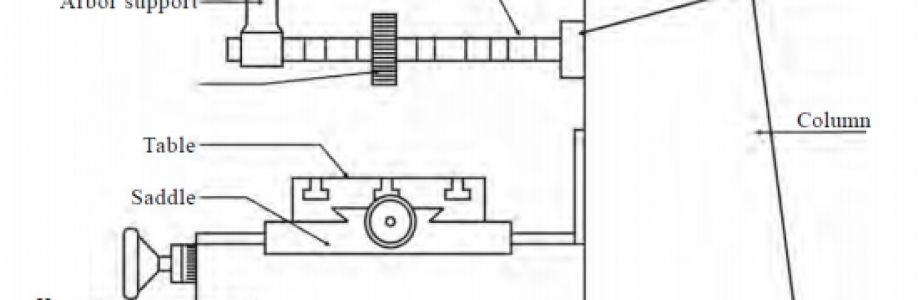

The column serves as a key support structure for the knee, worktable, overarm, and other components, as well as housing all of the spindle and table feed driving motors. The knee can be moved up and down along guideways in the column. The knee supports the saddle and allows the table to move vertically, allowing the depth of cut to be adjusted.

The simplest and smallest milling machine is the hand miller, which uses only manual feed for the table and power rotation for the spindle. It is utilized for tiny work such as slotting, keyways, and grooves. The tool is held by a horizontal arbor, and the table has three movements in most cases.

Milling in its most basic form Machine construction is comparable to that of a manual miller, but it is more durable. Power feeds are available in both horizontal and vertical orientations on the table. It is designed for more intensive milling operations. It also features a horizontal arbor on which is placed a cutting tool with a hole.

The cutter of the Universal Milling Machine can be rotated vertically or horizontally. It has more versatility and may be utilized for a variety of applications. Along with other milling processes, spur, helical, spiral, and bevel gears, twist drills, reamers, and milling cutters can be produced. It's possible to turn the table horizontally and feed it at an angle.

The spindle of a vertical milling machine is oriented vertically. Step milling is possible thanks to the little axial spindle travel. The most popular types of cutters are end mill cutters and face mill cutters. Grooves, slots, and flat surfaces are all produced with them. Auxiliary operations like as drilling and boring are carried out as well.